The Power of Focused Engineering

AMS Performance is an engineering company first, and our Snailworks Engineering Team approached the development of the BMW G8X M3/M4 Air Intakes with a single mission: maximize airflow and efficiency without compromise. Using advanced modeling, flowbench testing, and dyno validation, our engineers designed a system that dramatically reduces restriction and pressure drop across the entire intake tract. The result is a 128% larger cross-sectional area compared to OEM pipe, allowing the turbos to breathe freely for improved compressor efficiency, and consistent power increases all the way to redline.

To match both performance and aesthetics, the Snailworks team created two distinct variations: a premium carbon fiber lid version with magnetic fasteners for effortless filter servicing, and an open-top configuration featuring a powder-coated trim piece and premium stainless hardware for the ultimate in airflow and induction sound. Whether you choose the refined carbon enclosure or the aggressive open design, every component was engineered for precision fitment, strength, and real-world performance. This engineering-first approach ensures the AMS Performance G8X Air Intakes deliver measurable gains on the dyno — and a clear advantage on the road or track.

Slow is Smooth and Smooth is Fast

For maximum efficiency, the airflow path into the S58’s twin turbos must be as unrestricted and laminar as possible. Our AMS Snailworks Engineering Team engineered the intake ducting and silicone couplers with carefully optimized geometry to create a seamless transition between components, minimizing turbulence and pressure drop. Each connection is designed to maintain consistent cross-sectional area and smooth flow, allowing the turbos to breathe with less effort. To further enhance airflow, the filters themselves incorporate a radiused edge, reducing entry losses and ensuring the highest possible flow into the intake tract. The result is a system that decreases restrictions, improves turbo response, and delivers more power throughout the rev range.

Mo’ Powa Baby

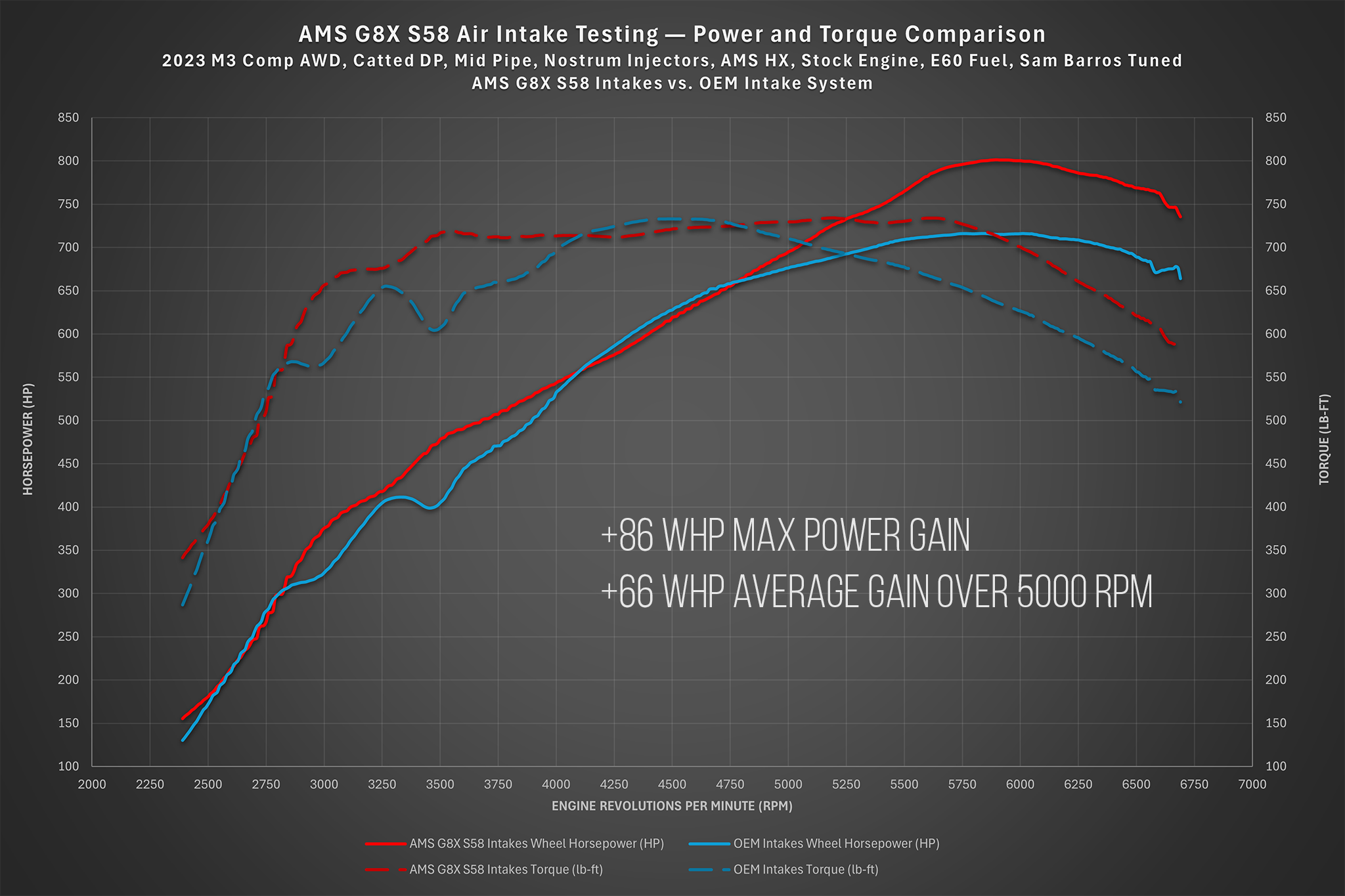

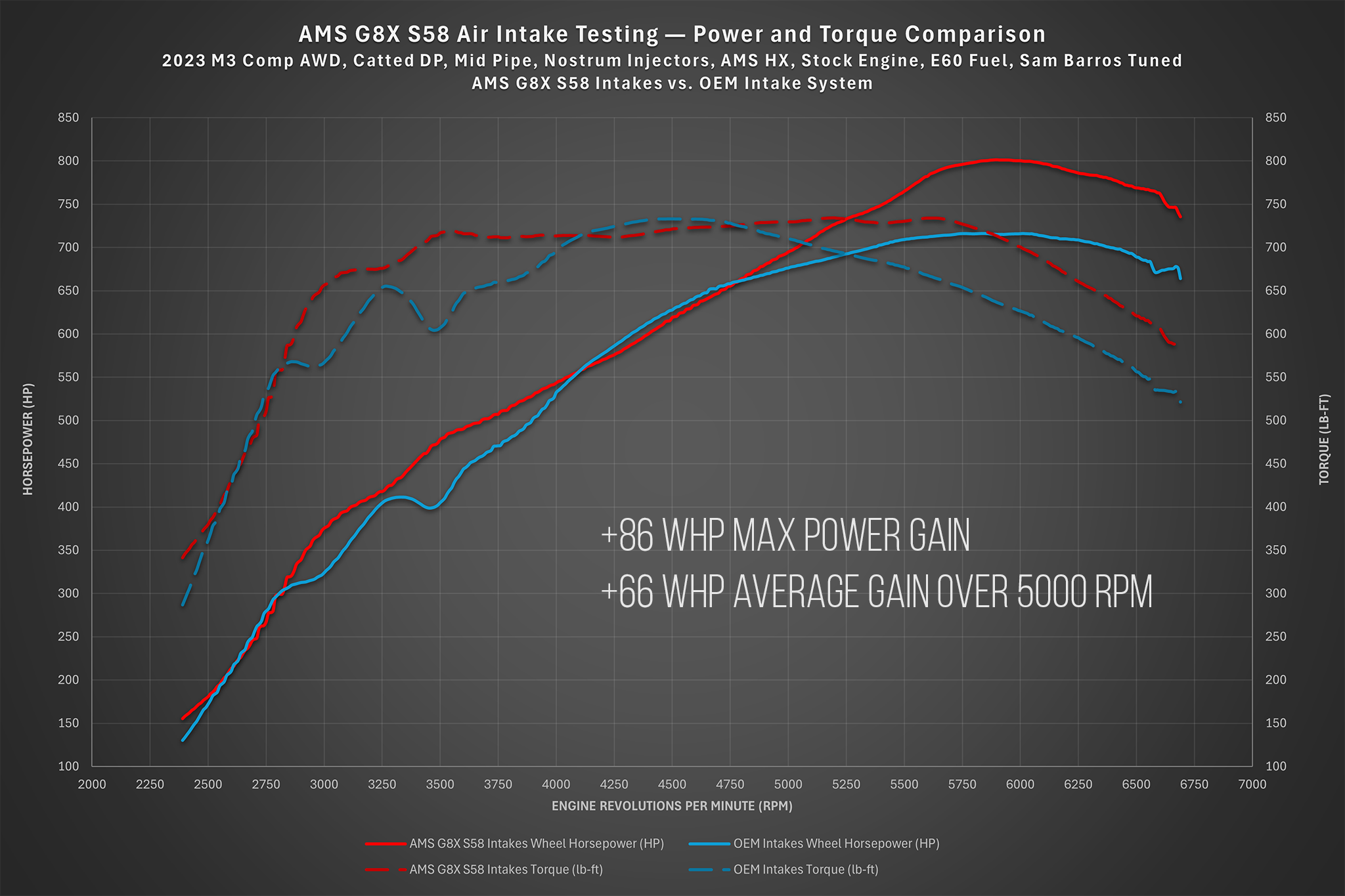

To validate the design, our AMS Snailworks Engineers performed extensive back-to-back testing against the factory intake system—and we didn’t stop there. Professional ECU calibrator Sam Barros conducted independent testing on his personal 2023 M3 Competition xDrive, equipped with catted downpipes, midpipe, AMS Heat Exchanger, Nostrum injectors, flex-fuel (E60), and our G8X intakes. Sam began by testing the OEM intakes at maximum tuned output, then installed the AMS S58 Intakes and again recalibrated the setup to take full advantage of the dramatically improved airflow. The results were outstanding, demonstrating that the system delivers reliable power gains in real-world, fully assembled driving conditions.

In Sam’s testing, the intakes produced an exceptional +86 WHP maximum gain over stock at 5900 RPM, with an average of +66 WHP above 5000 RPM and noticeable torque increases throughout the entire rev range. These gains translate to stronger low-end response, improved drivability, and significantly more top-end power. Simply put, the AMS Performance G8X M2/M3/M4 S58 Intakes set the benchmark for airflow, consistency, and real-world validated performance.

Results That Speak For Themselves

To quantify airflow gains with absolute precision, our AMS Snailworks Engineering Team ran the OEM intake, two leading competitor systems, and the AMS G8X S58 Intakes through our state-of-the-art MAF-based flowbench. Using MoTeC instrumentation to capture real-time pressure and airflow data, each intake was tested under identical, repeatable conditions that simulate the airflow demands of a ~600 WHP S58 engine. The results were unmistakable. The factory intake struggled, showing –2.15 psi of depression on the right intake tract, a clear sign of significant restriction. Competitor systems performed marginally better but still exhibited notable pressure drop. In contrast, the AMS S58 Intake System demonstrated a dramatic improvement with only –1.05 psi of depression on the right intake tract at the same airflow level—representing up to a 48% reduction in restriction versus OEM. At any given pressure drop, the AMS system consistently flowed more air than both stock and competitor offerings, making it the least restrictive intake solution in the test group. The AMS S58 Intakes also delivered nearly identical airflow results across both banks, demonstrating how well-matched the system is as a paired set—an advantage that promotes balanced engine performance and more consistent, predictable ECU calibration on each bank. The data speaks for itself: if you’re seeking uncompromised airflow and maximum horsepower potential, the AMS Performance BMW G8X M2/M3/M4 S58 Intakes stand alone at the top.

Track Tested, Race Proven.

When professional racer Jackie Ding put the AMS Performance BMW G8X Air Intake System to the test on his M2 race car, the difference was immediate and measurable. During dyno validation at AMS headquarters, our engineering team observed significantly improved airflow efficiency and reduced restriction, allowing Jackie’s S58 to carry strong power all the way to redline — a stark contrast to the OEM intake system, which tapered off sharply at higher RPM. On track, that translated into tangible lap time improvements: with sustained top-end power delivery, Jackie was able to stay in gear longer before shifting, maintain higher average speeds on straights, and achieve more consistent acceleration out of high-speed corners. The AMS G8X Air Intake not only unlocked horsepower on paper — it delivered a competitive edge where it matters most: at the finish line.

Product Notes

- The filters use specially designed media that allows performance and efficiency to be restored to near new each time by simply using compressed air (30-40 psi) from the inside out, making frequent washing unnecessary in order to restore filter performance. For a deep cleaning from extreme environments, a biodegradable cleaner such as Simple Green or other mild shop degreasers can be used. Simply place the filter in a solution or spray the cleaner on the filter. Allow the solution to loosen the particulate and then rinse thoroughly. Shake the filter or use compressed air from the inside outward to remove residual water and allow a full day or two to dry.

- As these motorsports grade carbon fiber parts are hand laid, slight imperfections or weave pattern variances can be expected.